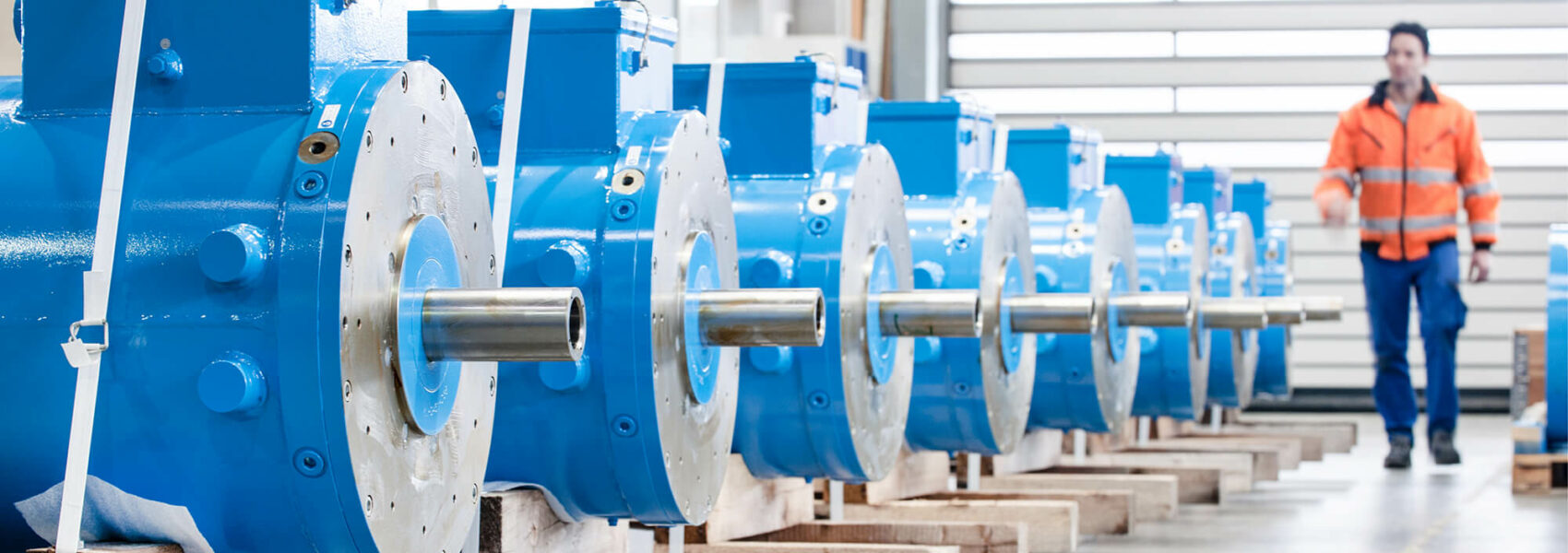

For Injection Moulding Machines, liquid-cooled three-phase asynchronous motors in both low and high voltage are used. Mainly employed are motors and pumps of the size 250 and 315 of a voltage range between 400 and 460 V as well as 75 and 460 kW.

Advantages Of Motors And Pumps For Injection Moulding Machines:

- Use of hydraulic oil as cooling medium and lubricants (maintenance-free storage – no additional service up to 5 years)

- Saving of space and weight due to compact construction (direct flange mounting and spline pins)

- Significant noise reduction and vibration-absorbing construction of the entire aggregate

- No heating of surrounding air resulting in saving of additional costs for both air supply and outlet

- Possibility to integrate constant displacement pump into hydraulic aggregate for partial-flow filter

Following Electric Motors Can Be Used In Injection Moulding Machines

Individual Manufacturing Of Motors For Injection Moulding Machines

ELIN Motoren develops and manufactures electric drives for your specific requirements!