Our test field is one of the most modern facilities in Europe. It offers the possibility to perform electrical tests on all synchronous and asynchronous machines – from routine to system tests. ELIN Motoren also offers mobile measurement and system solutions to perform diagnostics flexibly and worldwide.

- Total area: about 1000 m2

- Supply voltages: up to 15000 V

- Full load tests: up to 6 MW directly coupled

- Replacement procedure for asynchronous machines up to 15 MW

- Substitute procedure for synchronous machines up to 50 MVA

Electrical machine diagnostics: Long-term responsibility you can rely on

- Delamination

- Shrink hole

- Contamination

- Alterations to corona protection

- Humidity

Over the life cycle of rotating electrical machines, faults caused by operation or changes in the insulation and on the surface cannot be ruled out.

The purpose of electrical machine diagnostics is to detect faults at an early stage so that they can be rectified in good time. We carry out such machine diagnostic measurements with a diagnostic vehicle equipped according to the latest state of the art.

Loss Factor Measuring

If measuring commences in the course of manufacturing or at the stage of implementation, the result of loss factor measuring poses a characteristic for the engine. For repeated measurings, deviations in the tan-delta-curve imply alterations of the dielectric. Deviating measured results can be responded to in sufficient time. An ideal machine diagnostics or statement concerning the state of the insulation is possible by means of partial discharge measuring.

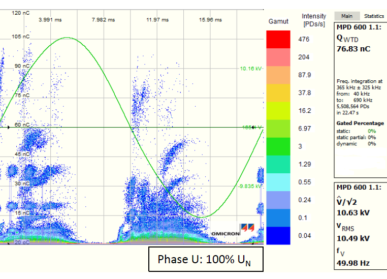

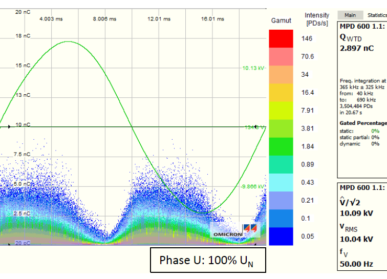

Partial Discharge Measuring

Insulation defects oftentimes leak electric discharges (partial discharges) which are detectable via partial discharge measuring. The clear advantage of these measurings is the information concerning partial discharge measuring spot, size and charge which can be gained. This technique also determines the new condition of the electric machine via reference measuring on-site of the manufacturer. Due to repeated measurings such as revisions, alterations in the insulation system can be determined via comparisons with prior measurings. An advantage of such machine diagnostics lies in the early stages of reaction, hence avoiding unexpected and expensive machine failure. Another asset is the condition-based maintenance and thus the planning of the budget.

Test your machine at our test facility or use our mobile test system.