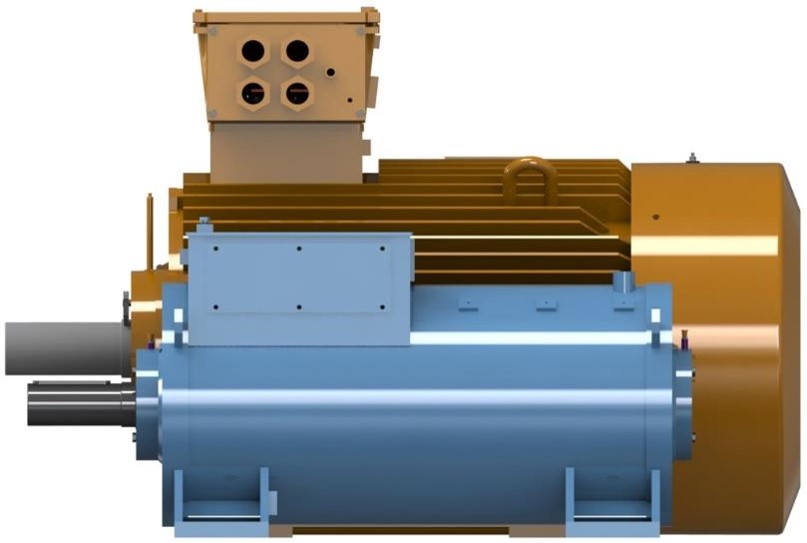

As a global expert for the construction of individual electric motors, ELIN Motoren is your professional partner in the field of plastics engineering. Our product portfolio for the plastics industry comprises liquid-cooled three-phase asynchronous motors in both low as well as high voltage sectors. Most frequently used are electric motors of a performance range in between 30 and 3.000 kW with common pole numbers and structures including protection types (up to IP68, Ex-d, Ex-e and Ex-n).

Electric Motors For Plastics Industry

In plastics technology, various machine types for various processing stages are required with standard solutions rarely proving suitable. As a pioneer in the manufacturing of water-cooled motors since 1973, we develop customized solutions with the highest degrees of flexibility for any field of application. Co-development stands for direct and fast communication, close collaboration and coordination with our customers. Hence, ELIN Motoren is able to offer premium solutions for the following application areas:

- Extruder Motors

- Pump Motors

- Compound Motors / Pelletizer Motors

- Motors For High-Pressure Pumps

- Hydraulic Motors

- Mixer Motors

- Motors For Calender

- Motors For Plastic Recycling Machines

- Motors For Injection Molding Machines

- Motors For Presses

As a globally operating specialist for electric machines, ELIN Motoren is your ideal partner in plastics technology.

Find the right product for your application in the plastic industry in just a few steps

Our electric motors for the plastic industry are perfectly matched to each application to achieve optimum efficiency for your plant.

Closed Motor Cooling-Systems

The completely closed cooling concept by ELIN Motoren is a crucial key component of our success regarding the manufacturing of asynchronous motors for the plastics industry having proved itself repeatedly under the harshest of conditions.

Advantages Of Liquid-Cooled Electric Motors:

- Space and weight reduction through compact structure and omission of interior fan

- Adaption of winding to customer requirements

- Robust towards contamination by dust and fluctuation of temperature

- Significant reduction of noise and vibration compared to completely closed and fan-cooled motors

- Cooled surface of motor casing reduces temperature of ambient air

- Water cooling allows operation on frequency converter over the entire speed range w/o additional cooling devices (no external fan required compared to air-cooled motors)

Size Comparison ELIN Motoren Type to AC Standard Motor

Water-cooled motors can be built more compactly than their air-cooled counterparts. Another technical advantage of ELIN Motoren is the exact adaption to the required operating point.

Following Electric Motors Can Be Used In Machines For Plastics Industry

ELIN Motoren develops and manufactures electric drives for your specific requirements!

ELIN Motoren – Sustainable Technologies For Future Generations.

We act cooperatively and professionally, generate customized solutions using flexible order processing in fast and direct communication while ensuring sustainable handling with our given resources.

We are pioneers and consider ourselves allies for our customers with the clearly defined objective to generate the highest customer value using state-of-the-art technologies with rotating electric engines and system solutions.

We are demanding – innovative – reliable – fair – sustainable

WE KEEP THE WORLD IN MOTION.