The marine industry is in constant pursuit of innovation, seeking propulsion systems that are not only efficient but also environmentally friendly. A growing awareness of the impact of noise pollution on marine ecosystems and human health has elevated the importance of silent propulsion testing. At ELIN Motoren we offer specific silent propulsion testing to mitigate noise in marine environments.

The Significance of Silent Propulsion Testing

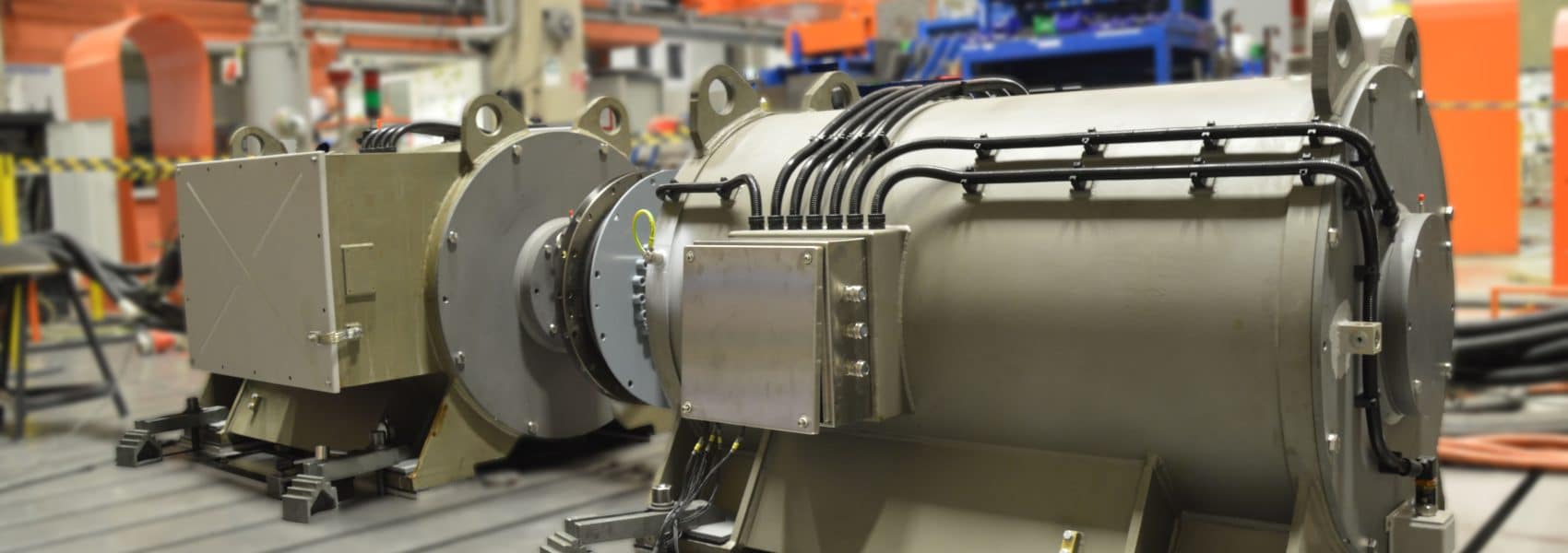

Silent propulsion testing plays a pivotal role in addressing several critical factors, e.g., minimizing environmental impact to protect marine life, ensuring the comfort of passengers and crew on board, and regulating compliance for industry sustainability and reputation. For this, electric motors utilized, for example, in research vessels, require a unique design and concept. The motor design must be optimized in previous studies regarding the reduction of mechanical and electromagnetic excitations. Our test field offers the infrastructure to simulate the mounting on the ship to check the vibrations transmitted to the foundation and the emitted noise for different operating conditions.

- Optimizing the propulsion system

This involves running the machines at various operating points, configuring them in a back-to-back arrangement to simulate the noise and vibration behavior for the specified operating conditions. - Structure borne noise testing

Using our acceleration sensors we measure the amplitudes and frequencies of machine- and foundation-vibrations, their frequency responses as well as resonances. - Airborne noise testing

With our sound-level-meter the emitted sound power amplitudes and frequencies of the motor are measured.

Airborne Noise Testing

Airborne noise testing evaluates noise that is directly emitted to the surrounding air. Key methods and technologies include the following:

- Sound Pressure Level (SPL) measurements

SPL measurements assess the intensity of noise emissions at various frequencies, which enables to identify the sources of noise. - Sound Intensity Level (SIL) measurements

The measurement of the sound intensity allows the evaluation of the sound power in a noisy environment. This method isolates the sound power of the motor in an environment with several noise sources to enable the testing of the motor at rated load in a back-to-back setup with auxiliary equipment (Inverter, etc.). The measurements identify the areas requiring noise reduction measures. - Acoustic Imaging

Acoustic imaging technology provides a visual representation of noise sources, aiding in pinpointing and mitigating the loudest areas of emission.

Structure-Borne Noise Testing

Structure-borne noise, the sound waves transmitted through solid structure may generate underwater radiated noise (URN). This is the case when propulsion system vibrations transmit through the hull into the water. To reduce the transmission of structure borne noise from the motor to the hull special focus must be set on the design of the bearing, and the evaluation of the vibrations transmitted through the bearing to the foundation. Special vibration measurement set ups and methods like experimental modal analysis ensure the verification of the designs effectiveness to reduce noise transmission.

Acoustic materials

Acoustic materials are crucial in airborne and structure-borne noise performance of electric motors and these materials must be strategically chosen and applied to minimize sound propagation and vibrations coming from the electrical machines. For airborne noise mitigation, sound-absorbing materials, such as acoustic insulation and barriers, are utilized to reduce the transmission of motor-generated noise through the air, ensuring low noise radiation. Simultaneously, for structure-borne noise mitigation, isolating materials are employed to minimize vibrations transmitted through solid structures e.g. the hull of a ship. The selection and application of appropriate acoustic materials and their effectiveness is verified with the various air borne and structure borne noise testing methods.

By investing in comprehensive noise testing, marine manufacturers and operators not only ensure compliance but also contribute to a healthier and more peaceful marine environment.