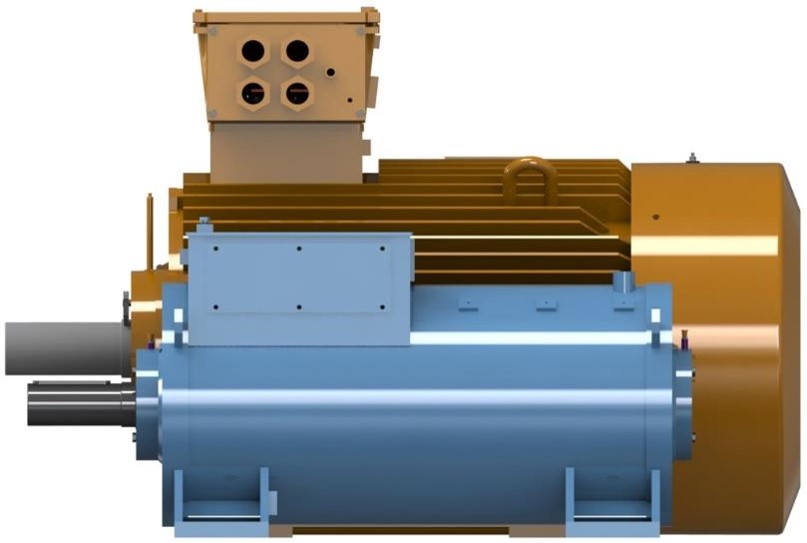

In the plastic and rubber processing industry, where innovation propels progress, water-jacket-cooled electric motors reshape the landscape with a more efficient heat dissipation mechanism, ensuring that the motor operates within optimal temperature ranges. Unlike their traditional counterparts, water-jacket-cooled motors maintain a controlled and consistent operation temperature. This addresses the persistent issue of overheating and marks a significant stride towards improved performance and reliability. By mitigating the detrimental effects of excessive heat, these motors stand for an efficient and sustainable drive solution.

High dynamic operation

and power density

![]()

No dangerous ignitions

due to independent cooling air

Significantly smaller

and more compact

![]()

Robust and reliable leading

to less maintenance effort

What are the advantages of a water-cooled electric motor?

Water-cooled solutions offer significant advantages when it comes to electric motors for extruders, mixers, injection and blow molding machines. This cooling system excels in efficiently dissipating heat, ensuring optimal performance and longevity of the motor. By utilizing water as a cooling medium, they effectively remove excess heat generated during operation, allowing the extruder to maintain consistent and reliable production levels even under high loads. A water-cooled electric motor offers the advantage of reduced size compared to an air-cooled solution. This is particularly beneficial when meeting customer-requested nominal points. The water-cooled system proves to be more effective in achieving the desired performance while maintaining a compact design, meeting the customer’s requirements efficiently.

As we conclude our exploration into the versatility of water-jacket-cooled motors, the picture that emerges is one of innovation meeting the diverse needs of the plastic and rubber processing industry. From injection molding machines to extruders that demand precision to the dynamic and sustainable world of plastic processing, these motors showcase adaptability and reliability.

25 Times better thermal conductivity than air

A motor with water cooling can operate more dynamically due to waters` 25 times better thermal conductivity than air. The flow-optimized water jacket transfers thermal losses directly into the cooling medium and thus enables a higher power density. A compromise between a small motor with high dynamics but low torque and a large motor with low dynamics but high torque no longer must be found here. Due to the excellent heat dissipation, the water-cooled motor is the ideal solution for dynamic load points. Extruding the pipe at a lower temperature and cooling it evenly inside and out reportedly improve pipe quality by reducing residual stress.

References

Improve the overall efficiency of your plastic and rubber processing plant